Control engineering

With more than five years of work experience in the automotive industry, we can safely say that it is our greatest specialty.

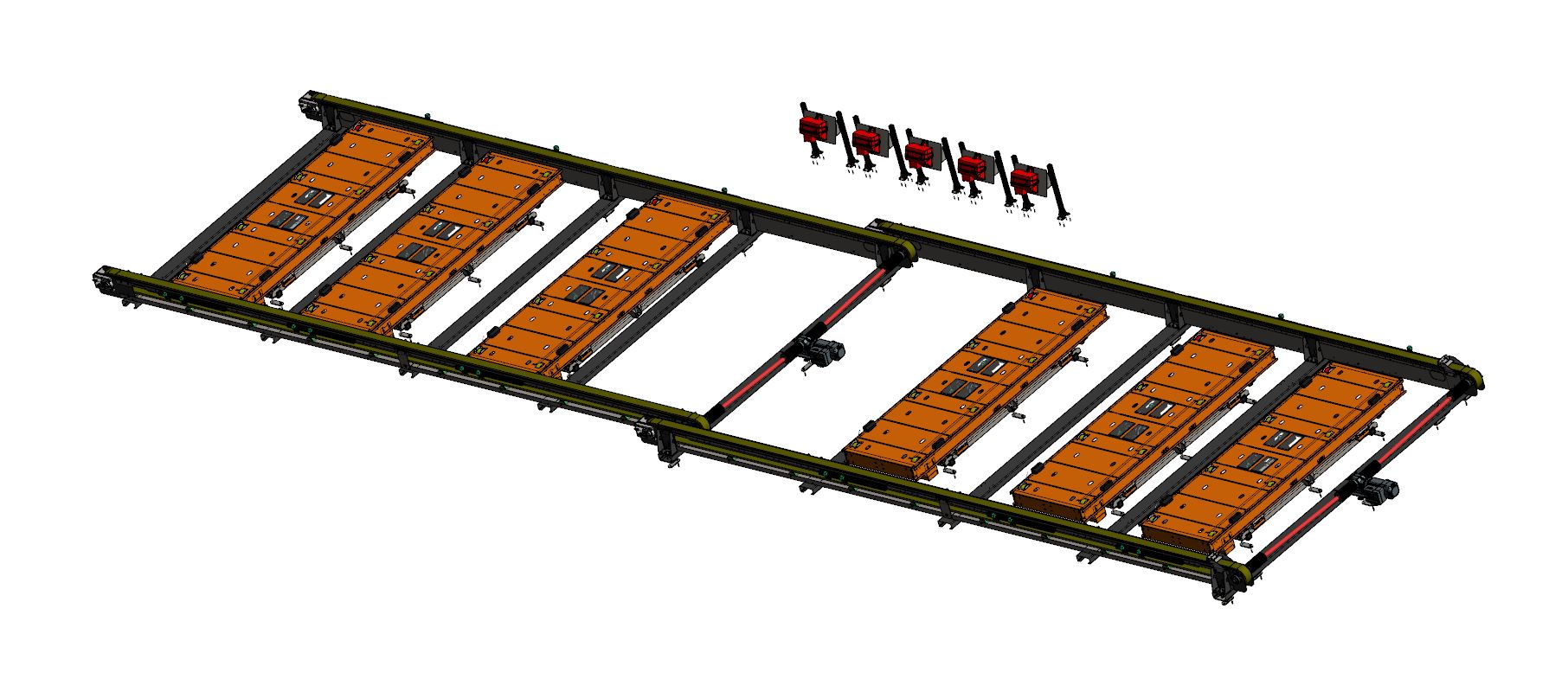

And we specialize in the creation of control software for body transport technology through the production process, most often through the paint shop, but we would also mention projects within the BIW (Body In White) area as well as the MFE (Material Flow Engineering) area.

The car body is usually transported on a skid. Depending on the factory, the paint shop is usually divided into several subsystems, i.e. PLC areas, and in each area a certain body treatment takes place.

The largest greenfield project we worked on for two and a half years (software development, commissioning and finally production support) had as many as 16 PLCs, of which we were responsible for as many as 14 of them!

We usually develop the control software within the existing standard of the car manufacturer, however we have also developed our own control blocks in case the client is flexible or does not have his own standard.

The hardware we work with is usually from the most famous manufacturers of industrial automation equipment – Siemens, Schneider, Rockwell Automation (Allen-Bradley), SEW Eurodrive, PILZ, Danfoss, Keyence, Banner, SICK, Leuze…

In addition to control software, we also develop safety software for all safety areas within the PLC area. Depending on the client, sometimes this software is programmed on the same PLC as the control software, and sometimes the client requires a separate PLC just for security purposes.

If you are looking for a partner company that would do the software part of the work for you, commissioning, project planning or everything – you are in the right place! Contact us, and we will guarantee pleasant cooperation and professional service with our experience and quality.